TLDW #25 - First Lighting of the Forge & Antique Habaki Utsushi

**WARNING: This is the longer process version intended for serious students of knifemaking. Watch the intro of lighting the forge here: https://youtu.be/jr4p5DCy4M0 ***more info below...

First lighting of the newly rebuilt charcoal forge in the island kajiba, more info on the project here: http://islandblacksmith.ca/tag/island-forge/ ...followed by stamping the tang and then hand forging and filing a classical tanto style habaki, silver soldered in the charcoal forge and closely based on an antique Edo period habaki. Polishing and patinating will be done after the saya has been carved.

The bending of the jacket is missing as the camera battery had died, that stage is shown in this video: https://www.youtube.com/watch?v=gyCsxnXKi0o

Watch the machigane area and you can see the solder begin to melt and flow around 26:52 until it is pulled out to stop the heating. The fuigo allows very precise air mix and heat control. When soldering habaki this way, some points are:

ensuring the fit is very tight (solder does not fill gaps),

cleaning the metal surfaces well to remove oxide and contaminants,

using a flux to prevent oxidation while heating (in this case borax and water),

forming a charcoal "oven" away from the direct air blast,

controlling the airflow for a reducing environment,

heating just to the flow temperature,

removing from the heat immediately,

allowing to slowly cool in air next to the coals,

pickling off any remaining flux in vinegar before fitting to the blade.

Note that silver solder (more accurately known as silver brazing or silver welding) is not at all related to electronics or plumbing solder, it is made from mostly silver and copper and requires far more heat and a different flux. In this technique the filler material actually forms a new alloy with the parent metals (similar to welding). It is more difficult to achieve but the results are very different and far stronger than lead or tin based solder joints.

The wire that binds the parts together, provides tension while heating, and forms the stand is a scrap piece of rusted steel wire, the oxide scale or rust helps prevent the solder from sticking and making it one with the habaki.

Machigane info: http://islandblacksmith.ca/2014/10/classical-tanto-construction-habaki-%25E3%2581%25AE-machigane/

Making habaki: http://islandblacksmith.ca/process/making-habaki/

Tanto geometry: http://islandblacksmith.ca/tag/tanto-geometry/

learn more about the historical knifemaking process: http://islandblacksmith.ca/process/

-

2:26

2:26

islandblacksmith

7 years agoSilver Soldering Habaki with a Charcoal Forge & Fuigo

886 -

11:27

11:27

islandblacksmith

6 years agoTLDW #19 - Bladesmithing at the Museum Swordsmith Forge

1.94K -

15:28

15:28

Red Beard Ops

11 months agoDIY FORGE Burner v2.0 | A Robust Forced Air Burner For Knife Making & Blacksmithing

111 -

26:05

26:05

Tyrell Knifeworks

1 year agoForging a Copper Damascus Katana

35 -

14:51

14:51

Old Is Gold

1 year agoForging a KATANA out of Rusted Iron CHAIN

119 -

10:54

10:54

Tyrell Knifeworks

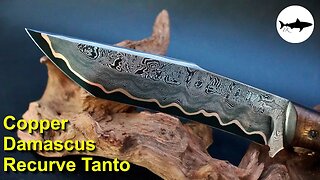

2 years ago $0.01 earnedForging a Copper Damascus Recurve Tanto Knife

441 -

6:07

6:07

1GiftWorld

2 years agoMaking The most Interesting & Beautiful 'Emerald' Necklace by Re-Purposing & Salvaging Materials

10 -

23:09

23:09

Creative Guise Productions (Maker)

5 months ago $0.04 earned12 Inch Brisket Knife in 5160 High Carbon Steel. Full Build

822 -

7:00

7:00

ROBUST BUILD

1 year agoMake an Easy & Simple Sharpening Station

19 -

42:35

42:35

Old Is Gold

4 months agoCompletely Abandoned & Rusty Electric Metal Cutter Restoration

82