#NASA has developed an additively-manufactured #rocketengine #nozzle made of aluminum, making

#NASA has developed an additively-manufactured #rocketengine #nozzle made of aluminum, making it lighter than conventional #nozzles, and setting the course for deep #space #flights that can carry more payloads. Under the agency's Announcement of Collaborative Opportunity, engineers from NASA's Marshall Space Flight Center in Huntsville, Alabama, partnered with Elementum 3D to create a weldable type of aluminum that is heat resistant enough for use on rocket engines. #Aluminum is lower density and allows for high-strength, lightweight components. However, due to its low tolerance to extreme heat and tendency to crack during welding, aluminum is not typically used for additive manufacturing of rocket engine parts.

The #RAMFIRE project focuses on advancing #lightweight, additively-manufactured aluminum #rocket nozzles. The #nozzles are designed with small internal channels that keep the nozzle cool enough to prevent melting. With conventional manufacturing methods, a nozzle may require as many as thousand individually joined parts. The RAMFIRE nozzle is built as a single piece, requiring far fewer bonds and significantly reduced manufacturing time.

#NASA and #Elementum3D first developed the novel aluminum variant known as A6061-RAM2 to build the nozzle and modify the powder used with laser powder-directed energy deposition (LP-DED) technology. Another commercial partner, RPM Innovations (RPMI), used the newly invented aluminum and specialized powder to build the RAMFIRE nozzles using their LP-DED process.

@NASA's moon to #Mars #objectives require the capability to send more #cargo to deep space destinations. The novel alloy could play an instrumental role in this by enabling the manufacturing of lightweight rocket components capable of withstanding high structural loads. "Mass is critical for NASA's future deep space missions," said John Vickers, principal technologist for #STMD advanced #manufacturing.

NASA and industry partners are working to share the #data and process with #commercial #stakeholders and academia. Various aerospace companies are evaluating the novel alloy and the LP-DED additive manufacturing process, and looking for ways it can be used to ma

-

2:01:47

2:01:47

Fresh and Fit

6 hours agoAfter Hours w/ & Tommy Sotomayor

127K251 -

34:19

34:19

Alexis Wilkins

13 hours agoBetween the Headlines with Alexis Wilkins: The Verdict and More

34.2K31 -

1:11:21

1:11:21

Kim Iversen

12 hours agoWW3?!? Is The West Secretly Behind Another Color Revolution Aimed At Toppling Russia? | Biden Maniacally Bombs Yemen and Russia

77.7K59 -

1:36:46

1:36:46

Roseanne Barr

10 hours agoFor Love of Country with Tulsi Gabbard | The Roseanne Barr Podcast #50

88.8K150 -

33:59

33:59

TudorDixon

17 hours agoA Story of Sacrifice and Service with Joe Kent | The Tudor Dixon Podcast

31.1K4 -

27:22

27:22

The Nima Yamini Show

9 hours agoAlpha Nima Crushes Nick Fuentes & Business Tips with Dylan

29.1K20 -

1:19:23

1:19:23

Mally_Mouse

8 hours agoLet's Hang - Cosplay Stream!!

46.8K2 -

1:05:06

1:05:06

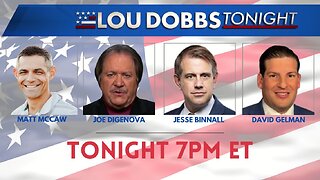

Lou Dobbs

15 hours agoLou Dobbs Tonight 5-31-2024

62.4K35 -

1:42:57

1:42:57

The Quartering

15 hours agoDonald Trump Conviction BACKFIRES, Massive Funds Raised, Democrats Swap Parties & More

99K98 -

26:11

26:11

Stephen Gardner

13 hours ago🔴HUGE TRUMP WIN! Biden, Hillary, Obama ALL IN BIG TROUBLE NOW!!

92.5K383