Automatic Spraying Booth - Toy Manufacturing in a Vietnam Factory

Automatic Spraying Booth - Toy Manufacturing in a Vietnam Factory

ChatGPT

Implementing an automatic spraying booth in a toy manufacturing facility in Vietnam can significantly enhance efficiency, quality, and safety in the production process. Here are some key considerations and steps to implement an automatic spraying booth in a toy manufacturing factory:

Regulatory Compliance:

Ensure compliance with local environmental and safety regulations regarding the use of spraying booths in manufacturing facilities.

Obtain necessary permits and approvals from relevant authorities.

Facility Layout and Design:

Assess the available space in the factory to determine the optimal location for the spraying booth.

Consider the workflow and proximity to other production processes.

Ensure proper ventilation and exhaust systems to maintain air quality.

Choose the Right Spraying Booth:

Select a spraying booth that is suitable for toy manufacturing, considering factors such as size, capacity, and type of spraying equipment.

Ensure the booth is equipped with proper filtration systems to minimize emissions.

Automation and Robotics:

Integrate automated spraying equipment or robots to enhance efficiency and precision.

Implement a programmable logic controller (PLC) system to control the spraying process and adjust parameters.

Safety Measures:

Implement safety features such as emergency shut-off switches, alarms, and proper protective equipment for workers.

Train personnel on safety protocols related to the spraying booth.

Quality Control:

Set up quality control measures to ensure consistent coating thickness and finish.

Regularly calibrate and maintain spraying equipment for optimal performance.

Employee Training:

Provide training for operators and maintenance staff on the operation and maintenance of the automatic spraying booth.

Emphasize safety protocols and best practices to minimize accidents.

Maintenance and Upkeep:

Develop a routine maintenance schedule for the spraying booth and associated equipment.

Keep spare parts on hand to minimize downtime in case of equipment failure.

Supplier Selection:

Choose reliable suppliers for the spraying booth and associated equipment.

Consider factors such as warranty, after-sales support, and the availability of replacement parts.

Monitoring and Optimization:

Implement monitoring systems to track performance and identify areas for improvement.

Regularly optimize the spraying process for efficiency and cost-effectiveness.

Environmental Impact:

Consider the environmental impact of the spraying process and choose environmentally friendly coating materials if possible.

Dispose of waste materials in accordance with environmental regulations.

Documentation:

Maintain comprehensive documentation of the installation, operation, and maintenance of the spraying booth for reference and compliance purposes.

By carefully planning and implementing these steps, you can integrate an automatic spraying booth into your toy manufacturing facility in Vietnam, improving production efficiency and product quality while ensuring compliance with safety and environmental regulations.

-

38:24

38:24

Tucker Carlson

9 hours agoTucker Carlson and Donald Trump Jr. Respond to the Trump Verdict

95.6K483 -

2:01:47

2:01:47

Fresh and Fit

10 hours agoOne Hit Wonder 🤡 Kicked Off For THIS...

171K357 -

34:19

34:19

Alexis Wilkins

16 hours agoBetween the Headlines with Alexis Wilkins: The Verdict and More

45.5K30 -

1:11:21

1:11:21

Kim Iversen

16 hours agoWW3?!? Is The West Secretly Behind Another Color Revolution Aimed At Toppling Russia? | Biden Maniacally Bombs Yemen and Russia

90.9K86 -

1:36:46

1:36:46

Roseanne Barr

14 hours agoFor Love of Country with Tulsi Gabbard | The Roseanne Barr Podcast #50

100K169 -

33:59

33:59

TudorDixon

21 hours agoA Story of Sacrifice and Service with Joe Kent | The Tudor Dixon Podcast

37K4 -

27:22

27:22

The Nima Yamini Show

13 hours agoAlpha Nima Crushes Nick Fuentes & Business Tips with Dylan

35K20 -

1:19:23

1:19:23

Mally_Mouse

12 hours agoLet's Hang - Cosplay Stream!!

52.7K2 -

1:05:06

1:05:06

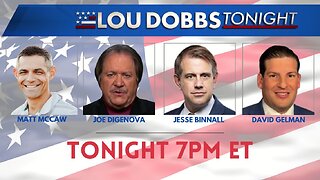

Lou Dobbs

18 hours agoLou Dobbs Tonight 5-31-2024

68.4K42 -

1:42:57

1:42:57

The Quartering

19 hours agoDonald Trump Conviction BACKFIRES, Massive Funds Raised, Democrats Swap Parties & More

105K117